Tyler Garman, president of The Roark Group, and an alumnus of the Walton College, donated materials, machine time and assembly labor to help create aerosol boxes for local hospitals and fire departments.

The aerosol box was designed by Dr. Hsien Yung Lai at Mennonite Christian Hospital

in Taiwan, and plans were made available free of charge under the creative commons

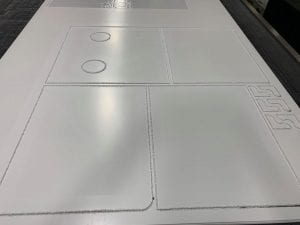

license. The plans describe a simple 50x50x40 centimeter, four-sided, ¼-inch clear

acrylic box, with two access holes for hands on one side.

The aerosol box was designed by Dr. Hsien Yung Lai at Mennonite Christian Hospital

in Taiwan, and plans were made available free of charge under the creative commons

license. The plans describe a simple 50x50x40 centimeter, four-sided, ¼-inch clear

acrylic box, with two access holes for hands on one side.

Doctors can use the box while intubating a patient to protect themselves from any particles that could be released from the patient’s airway during the procedure.

Dayton Castleman, director of visual thinking of Resource Design in Rogers, is managing and coordinating this project pro-bono on behalf of Resource Design.

Castleman reached out to his doctor, Joel Fankhauser, to see if he could help him assess the medical equipment need related to COVID-19.

Fankhauser then reached out to his friend at Mercy, Dr. Jason McKinney, intensivist, and asked what would benefit them, that designers could provide. McKinney responded with a link to the aerosol boxes and asked if they could make them.

Joel Gordon, making and tinkering manager of the Scott Family Amazeum in Bentonville, created the initial drawings and provided the first prototype to Mercy. Once Mercy approved the protype, Castleman reached out to local agencies that had the capacity to produce these boxes locally.

That’s when Garman, who earned a B.S.B.A. in 2000 from the Sam M. Walton College of Business, got involved.

Castleman said, “Roark put 100% skin in the game regarding production, which was great, because having a central source for producing these boxes allowed for an increase in efficiency, consistency and project flow.”

“When Dayton reached out it was perfect timing at Roark,” Garman said. “We have an amazing and talented team of makers, and due to the economic slowdown, we have some capacity. So, we were thrilled to have the opportunity to put our team to work on a project that can hopefully help protect our frontline caregivers.”

With this partnership they have been able to create 25 boxes for Mercy Hospital Northwest, 15 boxes for Arkansas Children’s Hospital Northwest and Little Rock, five for other hospitals that might need them and seven to the Rogers Fire Department that were modified to fit on their smaller stretchers to protect first responders.